Waste heat lab studies energy efficiency

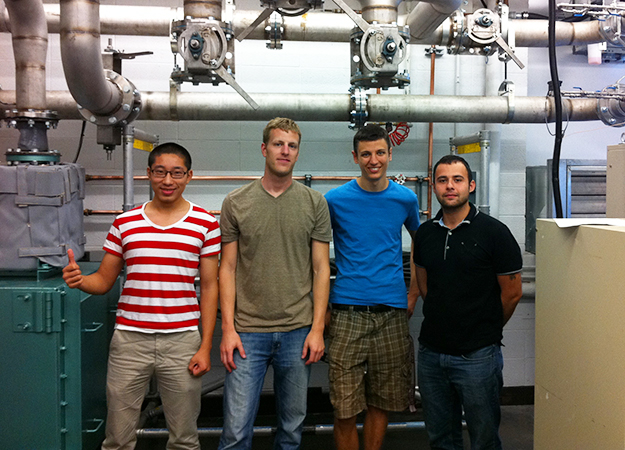

Undergraduate team members Yuxuan Cai, Adam Ritcey and Mitchell Terpstra (L-R) pose with graduate student Rafat Hirmiz inside the waste heat recovery lab.

A team of Mechanical Engineering students can proudly say, “I built that,” when it comes to showing off the University’s first waste heat recovery lab.

They may also be able to cook dinner in the process.

Constructed in the John Hodgins Engineering Building last summer, the lab was designed to study the recovery of waste heat from a variety of industrial applications. One of the long-term goals is to investigate, and hopefully improve, the efficiency of large industrial pizza ovens used in major fast-food chains – the kind that churn out dozens of deep-dish delicacies each day.

According to Mitchell Terpstra and fellow team members Yuxuan Cai and Adam Ritcey, far too much energy is wasted during the standard cooking process, with only a small percentage required to actually cook the pizza. Some of that wasted byproduct, says the team, can be stored and put to other uses, such as powering LED lights and signage, or providing hot water to the restaurant.

In order to put their theory to the test, the students obtained a large industrial oven from Pizza Pizza (one of the partners on the research project) and attached more than 800 kg of stainless steel piping to a natural gas turbine to study the excess energy. Each piece was meticulously measured, cut and welded to the turbine, along with a series of instruments designed to measure flow, temperature and pressure of the exhaust gas.

“It’s hard to estimate exactly how much time was put into this project,” says Terpstra, reflecting on the long, hot days spent assembling the machinery. “It was basically three people working all summer.”

Throughout the construction process, the student team was supervised by associate professor Jim Cotton, whose research in the Department of Mechanical Engineering focuses largely on energy efficiency related to heat transfer, HVAC (heating, ventilation, and air conditioning), refrigeration and waste heat recovery systems.

The facility was completed in part thanks to the students’ NSERC Undergraduate Student Research Awards – a program that fosters research partnerships between faculty members and undergraduate students, and provides $4,500 to cover 16 weeks of full-time research-based activity.

The focus right now is pizza, but long term, the team hopes the new facility will be used to study and promote more efficient uses of energy in a number of fields – from commercial or industrial ovens to automotive applications. One possibility is using the lab to study automotive drive cycles, which could have a major impact on everything from emissions to fuel consumption in the cars of tomorrow. With the McMaster Automotive Resource Centre (MARC) on the horizon, the timing couldn’t be more perfect.

The lab is currently being used by undergraduate and graduate students in the Faculty of Engineering, many of whom are conducting further research in the field of thermal management.